Diamond Cutting Discs: Accuracy Fuses with Endurance in Every Cutting Operation

Discover the perfect blend of precision and durability with our diamond cutting discs. Elevate your cutting operations to new heights today!

If you've ever worked in construction, fabrication, or even a DIY home makeover, you already understand how important a good cutting disc is. You don't think about it until your blade lags halfway through the tile or goes up in flames attempting to cut through stone.

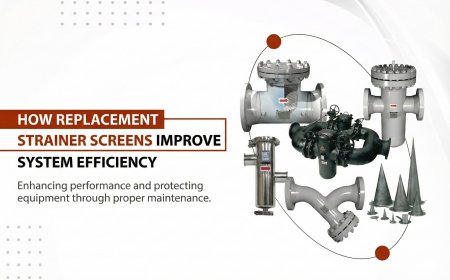

What Sets Diamond Cutting Discs Apart?

Most of the abrasive wheels will do the trick. But if you've ever machined through hard-to-cut materials like granite, porcelain, or reinforced concrete, you've likely watched a lower-priced disc lose its cutting power or fracture under stress.

Diamond cutting wheels are different. They are manufactured in heavy-duty diamond grit, which is attached to the cutting edge. These particles not only sharpen, they sharpen and sharpen, keeping the cutting edge keen. The result is a cleaner cutting, long-lasting wheel that is much more heat and wear resistant than standard wheels.

This is the reason why they can be used in demanding uses - you can be cutting bricks, pieces of stone, and tiles in your bathroom renovation.

Purchasing the Appropriate Cutting Disc to Use

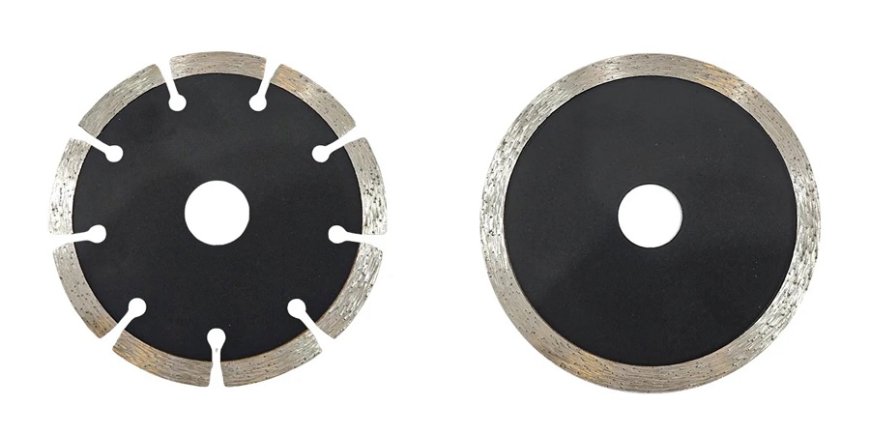

When choosing a cutting disc, you should not do that based on size. Lost focus on the disc form, on the manufacturer you are using, and on the strength of the machine in which you are utilizing. Diamond discs on some are discontinuous and on others are continuous, rimmed to cut quickly through hard material and with a smooth chip-free finish, particularly when cut on glass or delicate tiles.

Consider it in terms of footwear. You would not jog in steel-toe boots. Similarly, you wouldn't cut precision tile cuts in a high-end kitchen installation with a segmented blade. If you consistently work with hard materials, a quality diamond cutting disc will pay for itself over time in reduced costs, time, and headaches.

Why Professionals Use Diamond Cutting Discs

Speed is one aspect. Accuracy is another. Consistency is what sells most professionals on a diamond disc. A typical abrasive wheel will go through ten or fifteen tiles before it starts to wear. A high-quality diamond cutting disc may last that many times as long, yet still provide the same clean edge from the first cut to the last.

And, there's less drag, so less heat and a diminished risk of marring what you're cutting. That matters as much for your materials as it does for your tools. In landscaping, tiling, construction, or restoration work, having a disc you can rely on matters when time is of the essence.

Where to Find the Right Disc

You don't require an entire box full of solutionsyou just require the correct one. AbrasiveStocks is committed to providing discs of industrial quality that are put through real-world testing. The diamond cutting discs offered here are made for performance, designed to last, and designed for individuals who regard their work as serious business.

Final Thoughts

Cutting discs is not difficult, but as the pressure increases, time is of the essence, and more importantly, cuts are of the essence. This is where the usability of a diamond cutting disk comes into play. It is a resolute, accurate, and durable tool that not only does the job but even steps it up a level.