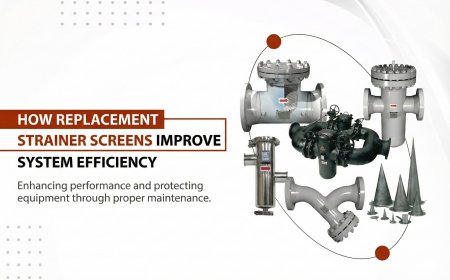

How Replacement Strainer Screens Improve System Efficiency

Learn how replacement strainer screens and fabricated simplex basket strainer setups support higher system efficiency with cleaner, safer, long-lasting flow.

Better performance in any fluid system is usually achieved by maintaining cleaner flow, which is why engineers and operators rely on replacement strainer screens. Removing particles before they cause damage helps the system run more steadily and efficiently.

A story is often shared from busy facilities where flow had been slowed by debris. A simple screen change brought the system back to life within minutes. Confidence grew because unwanted disruptions were avoided.

A similar change has been embraced in many operations using afabricated simplex basket strainer, where upgraded screens supported longer equipment life and smoother flow.

Why Are Clean Screens Considered Essential for System Reliability?

A system tends to lose strength when debris gathers. Many people have seen this happen without notice. The pressure drops quietly, valves struggle, and pumps work harder; all of this happens before failures appear. This is the moment when replacement strainer screens become essential. These screens block unwanted particles and protect every part downstream. A cleaner path encourages a more reliable flow and lowers stress on connected components.

The awareness of strainer replacement screens has grown across industries. Facilities have adopted structured inspection routines where strainers are checked, cleaned, and replaced before issues arise. A fabricated simplex basket strainer often becomes part of this plan because its design supports easy handling and consistent screening. Teams have shared stories of smoother days where downtime stayed low because simple care steps were followed.

Better screens also reduce operational strain. Pumps run cooler. Motors stay under less load. Flow gains stability. Debris no longer clogs process paths. The system environment becomes calmer and more predictable. Many readers appreciate this because production schedules stay on track. Operations stay aligned with safety standards. Unplanned stops are reduced, and energy costs become easier to manage.

Replacement strainer screens continue to support this stability, and a fabricated simplex basket strainer remains a trusted companion in every heavy-duty operation that values steady flow.

How Does a Screen Upgrade Improve Flow Quality?

In many facilities, it is often observed that when debris gathers, flow becomes uneven, movement becomes restricted, and noise increases. A simple upgrade using replacement strainer screens often changes this picture.

A screen with better mesh control manages more particles. The flow becomes smoother, pumps stop shaking, and valves respond with more accuracy. A fabricated simplex basket strainer holding the upgraded screen supports stable processing and clearer movement through the system.

Many operations have noted calmer performance right after the swap. Screening efficiency rises, pressure levels stay steady, and mechanical stress reduces.

Better screening encourages longer equipment life, which is always appreciated in demanding environments.

Why Do Well-Fitted Screens Lower Energy Use?

Energy use rises when systems struggle. Pressure loss often forces pumps to work harder. A switch to replacement strainer screens with proper sizing reduces this load. Flow becomes easier to handle, so the system demands less power.

A fabricated simplex basket strainer holding the right screen size prevents unnecessary turbulence. The fluid moves without heavy interruptions. This smoother movement lowers energy waste and keeps the overall system more balanced.

Operational peace is created when equipment does not fight against blockages. This peace leads to lower operating costs and a more predictable workflow.

Cleaner screens always support better efficiency.

What Makes High-Quality Screens Extend Equipment Life?

Equipment faces constant stress when debris is allowed through. Abrasion occurs, valves wear out, and pumps lose strength. Replacement strainer screens protect these components by catching harmful particles before damage forms.

A fabricated simplex basket strainer reinforced with durable mesh keeps contaminants away from critical machinery. This protection supports longer service cycles. Maintenance becomes easier, and equipment remains dependable over time.

Better protection also keeps emergency repairs away from daily operations. Production remains steady and confidence grows within the team.

Well-chosen screens act as silent protectors of the entire system.

How Do Proper Screens Reduce Downtime Risks?

Unplanned downtime disrupts every schedule. Many facilities have experienced entire days lost due to a small blockage. Replacement strainer screens help prevent these disruptions by capturing particles before they travel deeper into the system.

A fabricated simplex basket strainer adds another layer of stability because its structure allows debris to be collected efficiently. The cleaning process becomes quick, reducing the chance of extended interruptions.

A system supported by reliable screening stays operational longer. Pressure levels remain controlled. Flow stays predictable.

Better screening always lowers the risk of costly shutdowns.

How Does Regular Screening Improve Operational Safety?

Safety concerns increase when the flow becomes unpredictable. Blockages create pressure spikes. Components may fail under stress.Replacement strainer screenskeep these risks smaller by ensuring steady filtration.

A system using a fabricated simplex basket strainer gains additional safeguarding because its screen surface captures particles before they create hazards. Many operations value this because stable filtration reduces mechanical surprises.

Safer conditions emerge when every part of the system works without pressure shocks. Teams experience calmer working environments and fewer emergency interventions.

A clean screen contributes to a safer operation every single day.

What Final Benefits Come from Upgrading Screening Systems?

A facility searching for stable system performance often notices that every challenge begins with unclear flow. Debris travels unnoticed. Pressure becomes uneven. Components face unnecessary strain. However, stronger protection becomes necessary at this stage. Better outcomes are often created when replacement strainer screens are chosen with proper mesh support. Cleaner flow is achieved because particles are held back before harm is caused. Pressure settles into a steady pattern. Valves respond with more accuracy. Pumps remain under less stress.

Confidence grows when this change is paired with a fabricated simplex basket strainer. This structure keeps screening consistent throughout long operations. The flow path becomes calm. Movement stays predictable. Systems remain free from sudden restrictions. Energy losses are reduced. Wear on internal parts becomes slower. Maintenance teams feel relieved because surprises become rare.

The longer cycle of stability encourages better planning. Equipment life is extended because damaging debris never reaches sensitive parts. Production schedules stay steady because breakdowns remain limited. System operators appreciate the smoother rhythm created by dependable screening.

A cleaner and safer environment forms when upgraded screening is embraced. A fabricated simplex basket strainer continues to support this dependable and efficient way of working.